This month, both Cornwall County Council and Devon County Council's cabinet have declared a "climate emergency". Cornwall called on Westminster "to provide the powers and resources necessary to achieve the target for Cornwall to become carbon neutral by 2030"; Devon promised to forge "a county-wide partnership to ensure that Devon is carbon neutral by 2050". DCC's Cllr Roger Croad said:

There is a climate emergency and climate change will affect the environment, people, businesses and our prosperity.

That’s why we will be working with strategic partners to develop a plan to ensure that Devon is on the right trajectory to meet the IPCC’s carbon reduction recommendations.

County council pledges to meet UN emissions target as Devon becomes ‘carbon neutral’. It follows DCC declaring a climate change emergency and a commitment to work with strategic partners. https://t.co/cFhrq5UBAM pic.twitter.com/ggHyRhU138— Devon County Council (@DevonCC) January 28, 2019

All this comes as climate activism across the world appears to have moved up a gear: Children's climate rallies gain momentum in Europe; David Attenborough and Prince William take world leaders to task on environment, warning that humans have power to exterminate whole ecosystems ‘without even noticing’; Extinction Rebellion activists occupy Scottish parliament.

We are at a time in history where everyone with any insight of the climate crisis that threatens our civilisation – and the entire biosphere – must speak out in clear language, no matter how uncomfortable and unprofitable that may be.

We must change almost everything in our current societies. The bigger your carbon footprint, the bigger your moral duty. The bigger your platform, the bigger your responsibility.

Adults keep saying: "We owe it to the young people to give them hope." But I don’t want your hope. I don’t want you to be hopeful. I want you to panic. I want you to feel the fear I feel every day. And then I want you to act.

I want you to act as you would in a crisis. I want you to act as if our house is on fire. Because it is.

16-year-old activist @GretaThunberg, who has been camping outside the World Economic Forum in Davos, urges politicians to act on climate change pic.twitter.com/AtQTuUZTuc— The Guardian (@guardian) January 25, 2019

And indeed, our house is on fire. Our ecosystems are being destroyed. Look at the recent headlines:

Heatwave in Australia, again: Massive area with high temperatures over 45°C on Sunday. pic.twitter.com/JaXrjXaagd— Kees van der Leun (@Sustainable2050) January 14, 2019

More than 2,000 flying foxes die in Victoria's extreme heatwave https://t.co/JwXXe6eGtr— Guardian Australia (@GuardianAus) January 29, 2019

Hundreds of thousands of fish have died due to Australia’s record-breaking heatwave pic.twitter.com/QQRb7jEgJT— HuffPost UK (@HuffPostUK) January 28, 2019

Dozens of wild horses die of thirst in Australia's heatwave https://t.co/qlbt5Otflb pic.twitter.com/lcUDuQKWWc— CNN (@CNN) January 25, 2019

Meanwhile, in the northern hemisphere, Greenland's ice is melting four times faster than in 2003:

Greenland’s enormous ice sheet is melting at such an accelerated rate that it may have reached a "tipping point," and could become a major factor in sea-level rise around the world within two decades, scientists said in a study

This comes at a time when the Met Office predicts a 'worrying' rise in global CO2 forecast for 2019:

"Looking at the monthly figures, it’s as if you can see the planet ‘breathing’ as the levels of CO2 fall and rise with the seasonal cycle of plant growth and decay in the northern hemisphere," said Prof Richard Betts, at the Met Office’s Hadley Centre. "The graph is a thing of beauty, but also a stark reminder of human impact on climate. Each year’s CO2 is higher than the last, and this will keep happening until humans stop adding CO2 to the atmosphere.

"This news is worrying and compelling," said Prof Nick Ostle, at Lancaster University. "It represents a call to innovate with rapid and radical responses to offset these growing emissions."

We predict that in 2019, the annual mean CO2 concentration at Mauna Loa will be 411.3 ± 0.6 ppm— Richard Betts (@richardabetts) January 25, 2019

This is 2.75 ± 0.58 ppm higher than 2018 - a larger rise than most years in the record including the last two years, but not as large as 2015-2016https://t.co/EwwLrVF9Yy

Do such warnings make any difference to the world's polluters? Barclays has been accused of being on the wrong side of history with climate policy. What side of history will Aggregate Industries be on?

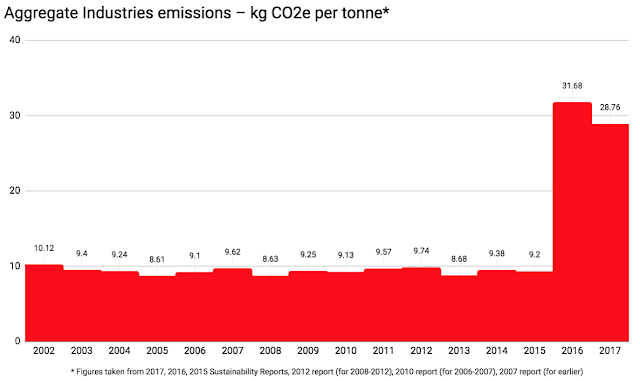

LafargeHolcim – parent of Aggregate Industries – has been accused of being the second worst company for increasing CO2 emissions, despite greenwash like this:

"The direction of travel for the industry is clear - reducing carbon emissions needs to be at the heart of everything we do." Barry Mellor of @AggregateUK on how greener #concrete could provide answers to the #constructionsector's most pressing issues 👇 https://t.co/9BS5veHWfO— LafargeHolcim (@LafargeHolcim) January 23, 2019

Of course, the company that claims "reducing carbon emissions needs to be at the heart of everything we do", is the same company that continues to plot a 2.5 MILLION MILE climate-busting haulage scheme across Devon.

“The only thing we can do is adapt and mitigate further global warming – it’s too late for there to be no effect,”— Paul Dawson on Climate Change (@PaulEDawson) January 22, 2019

“This is going to cause additional sea level rise. We are watching the ice sheet hit a tipping point."#ClimateChange #KeepItInTheGround https://t.co/m1S1Zic1g9